- Magnetic Pulleys

- Magnetic Take-Off Rails

- Cow Magnets

- Circular Vibratory Screens

- Demagnetizer

- Ferrite

- Handle Magnets

- Holding & Retrieving Magnets

- Hopper Magnets

- Magnetic Chuck

- Magnetic Conveyors

- Magnetic Coolant Filters

- Magnetic Hooks

- Magnetic Racks

- Magnetic Rods

- Magnetic Rollers

- Magnetic Sheet Floaters

- Magnetic Slide Conveyors

- Magnetic Stirrer

- Magnetic Sweeper

- Magnetic Tool Holders

- Magnetic Tubes

- Material Handling Magnets

- Prong Magnets

- Round Base Magnets

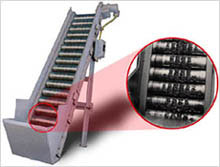

Home » Magnetic Rollers » Magnetic Rollers

Magnetic Rollers

Magnetic head rollers are designed to remove the metallic contamination from the materials on the belt. They are positioned at the head of the belt conveyors. The rotating roller holds the tramp metal and allows the clean material to pass smoothly. The magnetism dissipates as the belt leaves the roller, which led to the discharge of the unwanted contaminated materials. The contaminants are discharged into a separate receptacle. These type of magnet remove those metal from the product which are deeply embedded in the product and which has bypassed the magnetic field of other separator.| Electrographic Magnetic Roller A magnetic roller for electrophotography consist of a foamed resin magnetic material. This is produced by providing magnetic filler, a resin binder and a foaming agent in a closed mold. Foaming agent is activated in the closed mold which resulted in a roller which is later removed. |

- Easy to operate and install.

- Normally consist of high intensity rare earth magnets.

- They are continuous, permanent and power free.

- They are normally of stainless steel construction.

- The width of the roller vary for different magnets.

A

magnetic roller has applications in the following industries:

A

magnetic roller has applications in the following industries:

- Mining

- Refractory

- Feed mill

- Paper mill

- Chemical

- Plastic

- Ceramic

- Recycling industry